WELDING PIPE EUQIPMENTS

You are hear : Home > Products > Welding Pipe Equipments

FX114 High Frequency

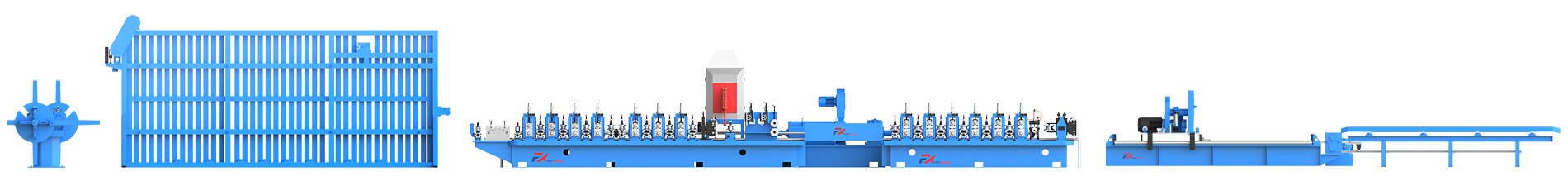

Welding Pipe Production Line

Welding Pipe Production Line

High frequency welding machine is a strip as raw material, after uncoiling, molding, high frequency welding, eliminate overip, sizing, straightening, cutting off a series of pipe forming process to produce complete sets of equipment or a variety of circular steel tube steel pipe line.

Roll forming is used to make the strip cold bending into round billet, and the welding seam is extruded to form round tube by high frequency induction heating. Various standard tubes and square tubes are produced after sizing.

Roll forming is used to make the strip cold bending into round billet, and the welding seam is extruded to form round tube by high frequency induction heating. Various standard tubes and square tubes are produced after sizing.

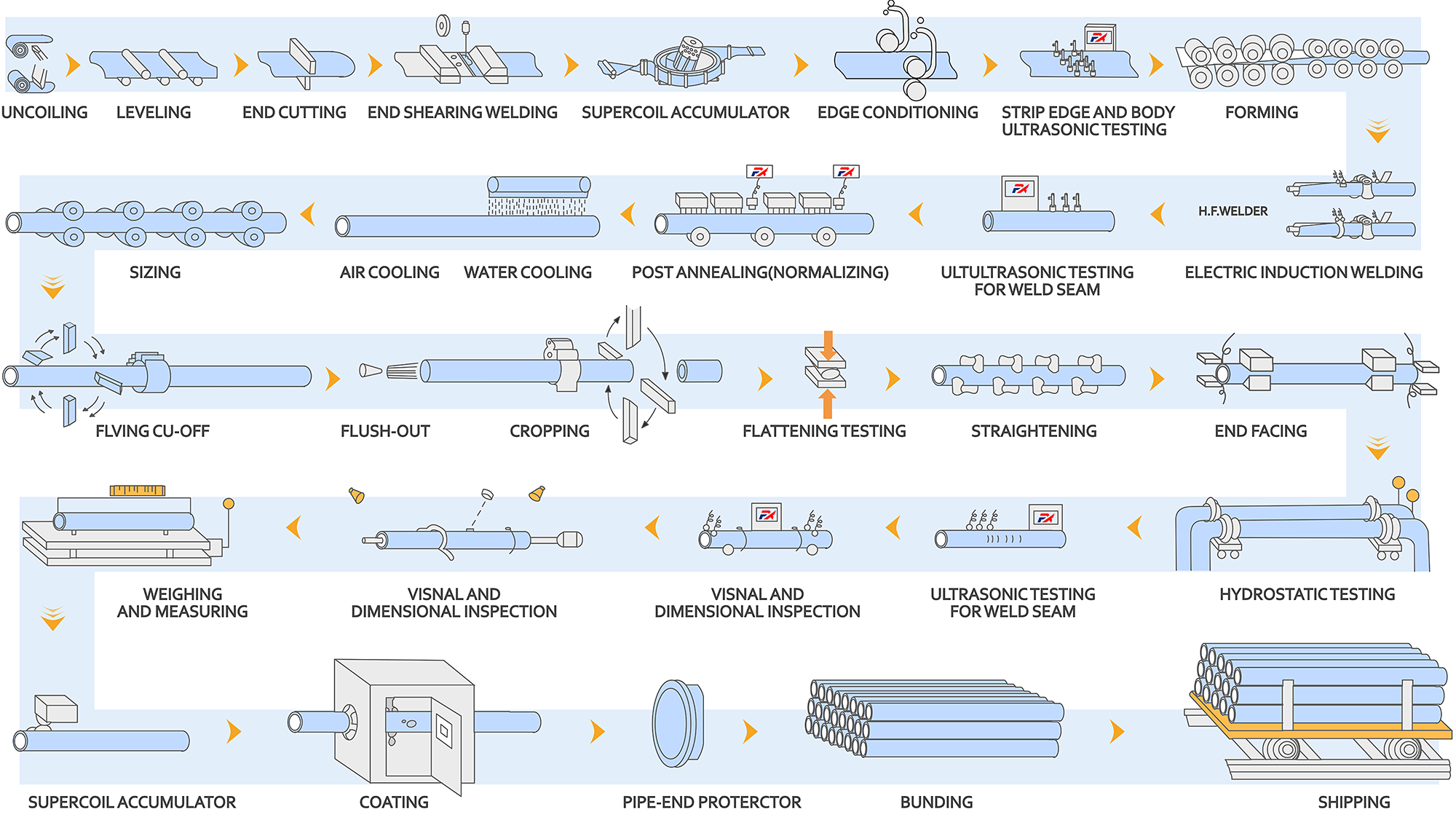

PROCESS OF THE PIPE PRODUCTION LINE

MAIN TECHNICAL PERFORMANCE

| Raw material | Carbon steel coil, galvanized steel coil, other hot or cold rolled steel coil. | |

| Pipe size scope | Width of raw material | 240 - 500mm |

| Round pipe outside diameter | Φ76 - Φ159mm | |

| Round pipe thickness | 1.0 - 4.0mm | |

| Square and rectangular pipe size | 60x60 - 125x125mm | |

| 40x80 - 100x150mm | ||

| Square and rectangular pipe thickness | 1.0 - 3.0mm | |

| High frequency induction welder power | 300Kw | |

| Production speed | 20 - 60m/min | |

| Total electricity power of the production line | 500Kw | |

INTRODUCTION OF MAIN EQUIPMENT

| NO. | EQUIPMENT | INTRODUCTION AND MAIN TECHNICAL PARAMETERSMANUFACTURER | |

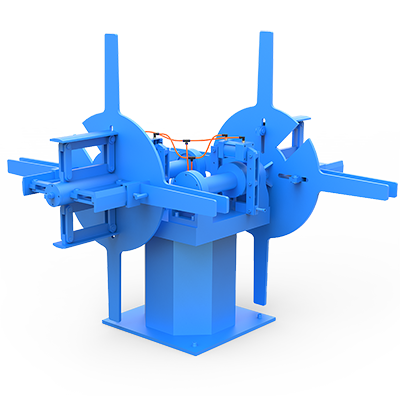

| (1) | Raw material uncoiler  |

It’s used to support the steel strip roll and feed raw material for the production line. | |

| 1) Structure mode | Single working position | ||

| 2) Material tray outer diameter | Φ1600mm | ||

| 3) Material tray inner diameter | Φ500 - Φ600mm | ||

| 4) Central height | 1000mm | ||

| 5) Weight bearing | 5000Kg | ||

| (2) | Horizontal material accumulator  |

It’s used to weld together the tail of former material roll and the head of next roll to ensure the continuous production of pipes. | |

| 1) Max storage capacity | 10Ton | ||

| 2) Power of motor | 22Kw | ||

| 3) Max material feeding speed | 120m/min | ||

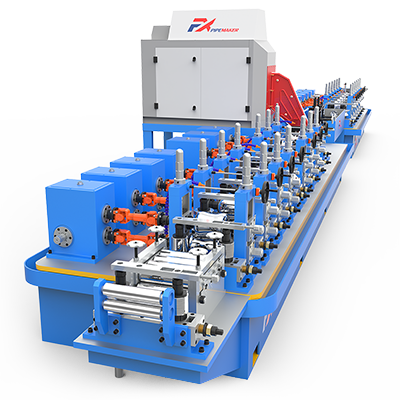

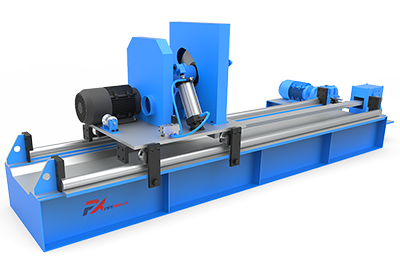

| (3) | Forming and sizing machine  |

It’s the main equipment of the production line. Rollers can make steel strip form into pipes of variety shapes. It consists of forming part , welding part and sizing part. | |

| 1) Forming part | Material feeding - Flattening - Feeding - 1 Horizontal roller - 1 Vertical roller - 2H - 2V - 3H - 3V - 4H - 4V - 5V - 6V - 5H - 7V - 6H - 8V - 7H - 9V | ||

| 2) Welding part | Seam direction guiding -Extruding - Welding - Weld burr removing - Polishing - Water cooling | ||

| 3) Sizing part | 1V - 1H - 2V - 2H - 3V - 3H - 4V - 4H - 5V - 5H - 6V - 6H - Speed measuring - Straightening | ||

| 4) Driving method | Two 160 Kw DC motors transmit power to gear boxes through reducer, then gear boxes transmit power to each horizontal roller through universal shafts. | ||

| 5) Horizontal frame | Using gantry type integral frame. Diameter of shaft is Φ90mm and the material is 40Cr. | ||

| 6) Vertical frame | Adjusted through lead screw. Diameter of shaft is Φ60mm and material is 40Cr. | ||

| (4) | Computer flying saw  |

With the high precision STD control system and quick reaction of mechanical system, the cutting saw has reliable synchronization performance and high precision cutting length. | |

| 1) Error in length | ±3mm | ||

| 2) Power of cutting motor | 45Kw | ||

| 3) Power of driving motor | 22Kw | ||

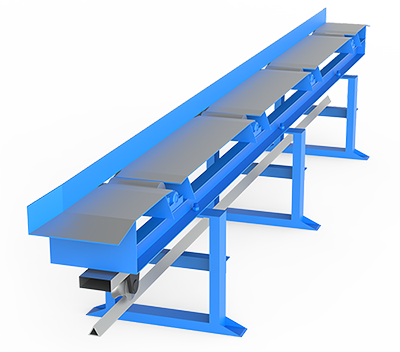

| (5) | Automatic pipe unloading

platform  |

It is an unloading platform of pipes cut by computerized saw. After the pipes falling down, workers can quickly check the quality and package them for preparation of transportation. | |

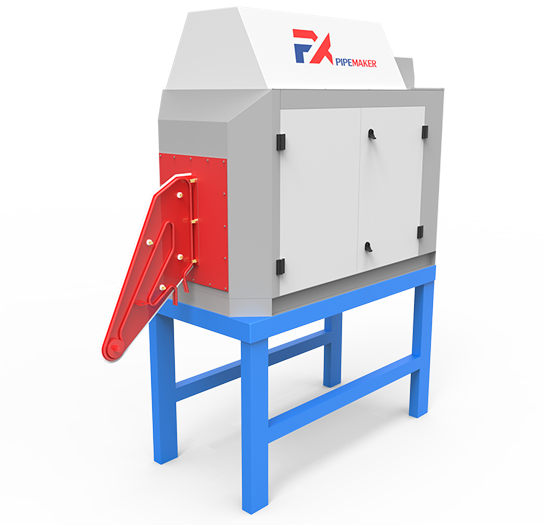

| (6) | High frequency induction

appliances  |

Using the current skin effect and proximity effect of high frequency to make both edges of the material rapidly heated to soldering temperature and then weld them together. Using computer to monitor the process can provide the machine with reliable quality. | |

ITEMS BUYER SHOULD PREPARE

• Workshop to place the whole pipe production line (more than 65×5m²) and

Space for high frequency appliances (more than 6×4m²)

line. Connecting wires from high frequency to the main machine

distance more than 25m)

Space for high frequency appliances (more than 6×4m²)

• Power supply: The main electric source to high frequency room and production

line. Connecting wires from high frequency to the main machine

• Water supply: Water pool (30m³) and one 2-inch self absorbing pumps (raising

distance more than 25m)

• Several saw pieces of the computerized saw according to the specification.

• Foundation of the production line to be constructed according to

drawing.

the material coil.

specification

• Gas supply: one air-compressor (1.0m³/min)

• One set of shearer and welder for connecting the head and tail of

the material coil.

• Induction loop(Φ10/12×1 copper tube) and magnet bar according to pipe

specification

MAINTENANCE & TRAINING

We can provide:

• Onsite full assembly services

• Spare parts for maintenance demands

• Spare parts for maintenance demands

• Free consultation of maintenance issues

• Oversea in/out country training program

• Oversea in/out country training program