Main Products

Main Products

Spare parts

Spare parts

M & T

M & T

as well as training programs

Photos & Video

Photos & Video

KNOW ABOUT

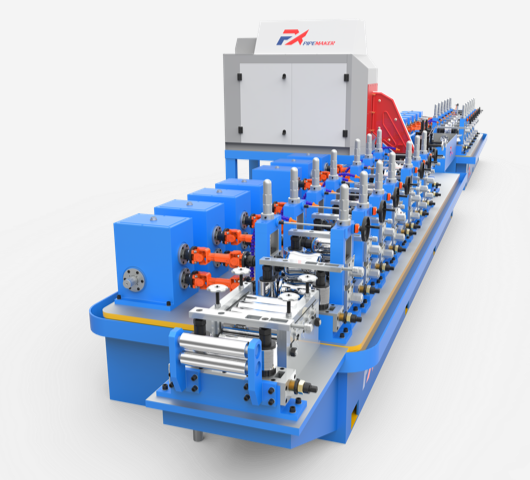

FX is idea of Firefox, we focus all-in-one solution provider

all-in-one lines of Cold-roller,Slitting machine, and pipe

welding machine etc.

We have exported and assembled over 1000 production lines over the past 15 years in more than 40 countries in South America, East Europe, Asia, Africa and Mid-East etc.

READ MORE